STELLA DEL SUD: the figs of Cilento distributed all over the world, guaranteed by PRISMA X-rays

STELLA DEL SUD: the figs of Cilento distributed all over the world, guaranteed by PRISMA X-rays

Stella del Sud S.r.l. is a company from Campania specializing in the cultivation and processing of high quality figs, which has been active for over 30 years and has long been on the international market. To face the challenges related to compliance with safety regulations and standards, a natural consequence of corporate and commercial growth, it has chosen to have PRISMA INDUSTRIALE at its side.

In this case history we see how the combined and high-performance 2XR11 + 08T3 solution made it possible to ensure both the absence of contaminants, thanks to X-ray inspection, and compliance with weight tolerances through the 08T3 checkweigher.

Stella del Sud

Stella del Sud S.r.l. was born in 1988 in Casalvelino to give a commercial development to one of the typical agri-food products of the Salerno area: the renowned white figs of Cilento DOP. Stella del Sud immediately distinguished itself for the quality of the raw material and for the ability to produce, through modern industrial processes, some of the specialties of the Cilento food tradition: dried figs, covered figs, filled figs, dried figs with chocolate, etc ... with over forty variations of processing and packaging.

The company operates on the national and international market, with the aim of increasing its shares in both and entering new sectors, while continuing to respect the highest level of product quality.

One of the packages controlled by the PRISMA combined system

Marketing also takes place through large-scale distribution, with which it was possible to establish distribution relationships thanks to the quality guarantee, ensured not only by the raw material, but also and above all by the controls installed on the production and packaging lines.

Quality first

Starting from a high quality raw material, Stella del Sud's goal was to keep the same level also on the processed and packaged product.

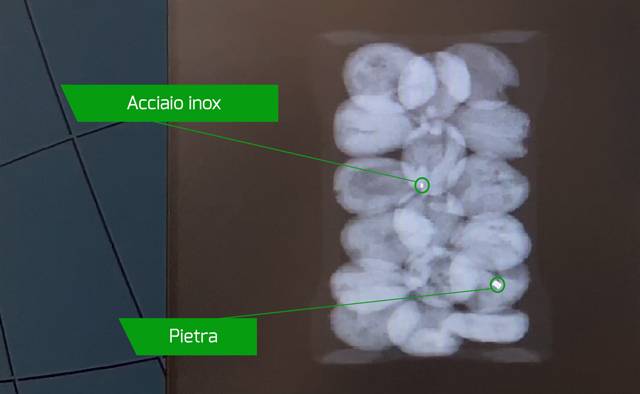

In addition to having to ensure the absence of metal pieces, a risk always present within a production line, one of the main problems was the presence of stones; a contaminant which, having a shape and color similar to that of figs, is difficult to distinguish by visual inspection, both human and automated.

Stella del Sud then turned to PRISMA INDUSTRIALE to find a solution.

As it was not possible to simply use a metal detector, PRISMA and Stella del Sud jointly evaluated the next level alternative for food inspection: inspection using an X-ray machine. A series of tests carried out on product samples containing different types of contaminants led to identify the perfect solution for this application in the 2XR11 X-ray food inspection system.

The low energy used by the system, in addition to ensuring safety for the operator, the product and a consequent streamlining of bureaucratic procedures for the use of the system, allows to obtain very high levels of sensitivity, coming to identify contaminants of 0.6 mm of stainless steel, even in a non-uniform product such as a pack of figs.

The great flexibility of the system makes it possible to inspect the extremely varied range of products and packages of Stella del Sud using a single tool, with a product change made easier by the Auto Set-up function of the latest generation software.

The requests of retailers, defined in the reference standards (BRC, Marks & Spencer, etc.) have thus not only been respected, but also overcome, protecting the brand from the risks leading to damage of image and product recalls.

However, the customer's requests did not end there.

An example of the contaminants detectable by the 2XR11 X-ray machine

An integrated solution with weight control

Stella del Sud already had the opportunity to test the quality of PRISMA checkweighers, and was satisfied with both in terms of reliability and performance. In this new line, however, it was necessary to implement a weight control compliant with the MID directive.

PRISMA, which was the first Italian company to comply its dynamic scales to European legislation, has therefore integrated the X-ray system with an 08T3 MID checkweigher, configured with a 500 mm in-feed belt for product spacing, by a weighing plate with double load cell (Dual System) of 300 mm and an output belt of 500 mm. A rejection system is installed on the latter, which is added to the one present on the 2XR11, in order to keep contaminated products and those with incorrect weight separate, as required by law.

Furthermore, both machines are equipped with an extremely intuitive touchscreen interface and have been supplied with all the preset recipes, thus minimizing start-up times.

The system combining the 08T3 checkweigher and the 2XR11 X-ray machine

Dozens of packages, one supplier

One of the main challenges faced consisted in designing a combined system that carried out a double control, complete with separate waste systems and able to easily manage the dozens of different packages that make up the Stella del Sud catalog.

A goal that is not easy, but that has been achieved without difficulty, thanks to the flexibility and modularity of the systems, the numerous options, the experience of 37 years and above all the fact that PRISMA produces both systems directly, without the need to ask third parties, thus placing itself as a true 360° partner for everything concerning inspection and quality control.