History

40 years of ITALIAN technology exported all over the world

PRISMA INDUSTRIALE S.r.l. was born in 1984. More than 40 years of history and achievements that made PRISMA brand a reference point for inspection and quality control.

-

1984 - 1988

The company PRISMA INDUSTRIALE S.r.l. is founded and the first dynamic cell checkweighers are created, among the first produced in Italy.

PRISMA steps into the national market, participating in the 1985 Ipack-Ima trade show: the first big job orders come in.

-

1989 - 1993

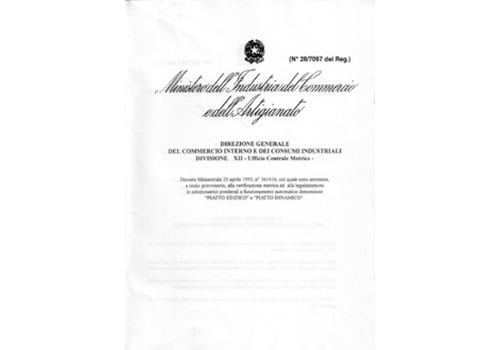

The Ufficio Metrico (Italian Weights and Measures Office) approves PRISMA checkweighers for legal use. The first C3-C8 electronics are created.

The PRISMA product line is enhanced with food metal detectors, among the first made in Italy.

The quality of PRISMA machines begins to be recognised even abroad, kicking off the internationalisation process and export to European countries.

Inauguration of the new headquarters in Via la Bionda 17 and restyling of the company logo, based on the concepts of technology and innovation.

-

1994 - 1998

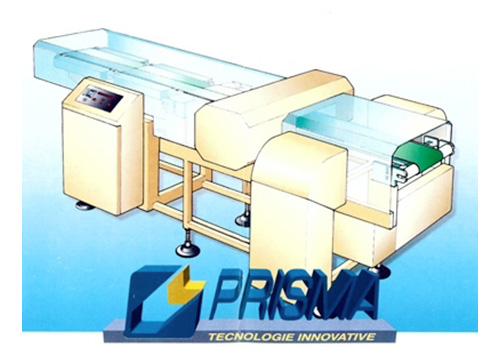

The “Quality” solutions are born, machines integrating metal detectors and checkweighers.

The company’s internationalisation leads to branches opening in France and Spain.

-

1999 - 2003

New D3 electronics are developed.

PRISMA’s micro-leak detector, the “Sniffer”, is created.

Widening of the product range, with a complete line of checkweighers and metal detectors; increased production leads to expanding the headquarters, which doubles in size.

-

2004 - 2008

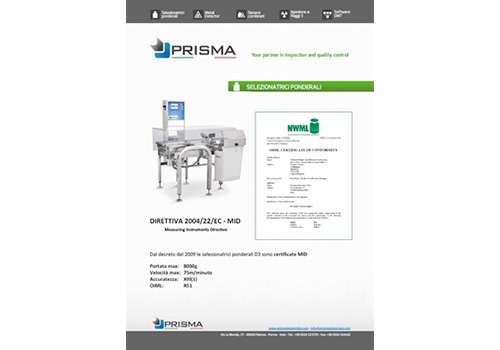

D3 checkweighers obtain MID approval.

PRISMA INDUSTRIALE S.r.l. obtains ISO 9001 and 14001 certifications. The first compact integrated 08D3 is born, the first and, still today, only integrated machine made entirely in Italy.

The metal detector range is enhanced with the MDC11 - MDF11 models.

PRISMA makes commercial and distribution agreements with important international businesses.

-

2009 - 2013

PRISMA builds its Metrology laboratory and the Research and Development Centre opens in via della Valle.

The first machine models made of mirror finished stainless steel are created.

T3 electronics with touchscreen displays are born.

The 01W3 checkweigher is created, with electromagnetic compensation cell.

Out of the partnership with Auteco comes the DMT Software for production analysis and control.

The VT02 model is created, PRISMA’s Track & Trace to mark and check the serialisation of pharmaceutical products.

The brand and entire company image is restyled, based on the concepts of experience, sustainability, quality and Italian company identity.

-

2014 - 2018

PRISMA launches onto the market the 2XR11 model: the X-ray inspection according to PRISMA INDUSTRIALE.

X-ray inspection systems complete the products range, making of PRISMA the only one offering a 360° inspection and quality control.

The new MID-approved, T3 compact integrated system is born.

MID approval extends also to the T3 models.

The new PRISMA metal detectors are presented.

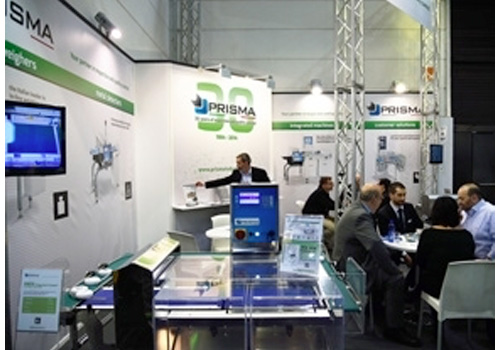

PRISMA INDUSTRIALE S.r.l. celebrates its first 30 years with an exhibit at Interpack 2014, the most important international event dedicated to packaging.

Two product lines are established: Standard MACHINES - Special SYSTEMS.

-

2019

PRISMA crosses the line of 35 years of activity and celebrates renewing its corporate image

On the occasion of Cibustec 2019 several new products are presented; among these, the innovative model 2CW31, the checkweigher for product classification up to six weight groups. Ideal for weighing products with variable weights and for association with a downstream classifier, this product opens up new markets and development opportunities for the company.

-

2024