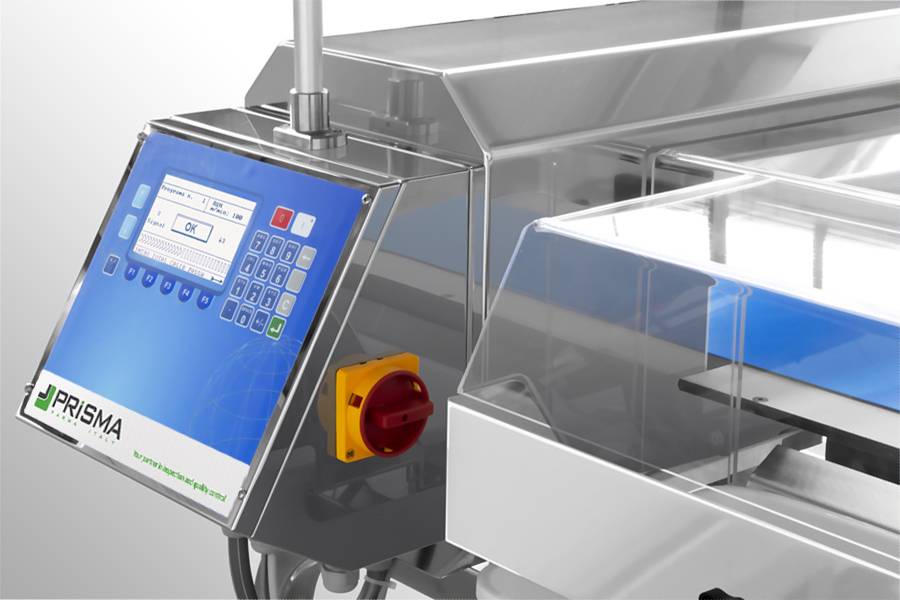

MFN11 with 60 conveyor

MFN11 with 60 conveyor

Inspection systems

Conveyor metal detector for food industry, ideal for inspecting small and medium sized loose and packaged products.

The multi-frequency electronics, combined with advanced functions - like self-check, automatic calibration and tracking - guarantee top level performance and fully meet the most common standards (including, among others: BRC, Marks & Spencer...) and the need to minimise false rejects.

The possibility of configuring both conveyor stop and the rejection and reject collection systems allows you to configure the machine based on the checking needs and the available budget.

A wide range of available accessories allows you to configure the machine in the most suitable way to inspect the most common formats in the food industry like: trays, sacks, bottles, boxes of different shapes and sizes with no metal parts.

The transit aperture inner ring in food-safe plastic allows the machine to be used even with loose product.

| Weighing range | up to 10000 g |

|---|---|

| Linear speed | up to 65 m/min |

| Pneumatic supply | 0,6 Mpa |

| Air consumption (for ejection) | 1 Nl |

| Power supply | 230 V 50/60Hz single-phase |

| Power consumption | 650 W |

| Mirror finishing of metal parts | Stainless steel IP54-IP65 |

| Climatic environment | from 5°C up to +40°C non-condensing (closed) |

| Regulations | Conformity with CE regulations and with international standards for Electrical Safety and Electromagnetic Compatibility |

Multi-frequency technology

The multi-frequency electronics result in high-level immunity from environmental interferences (dry, humid, cool and frozen) and extremely high sensitivity to all magnetic and non-magnetic metals, including stainless metals, thereby guaranteeing top level performances.

Simple, functional electronics

Digital electronics with alphanumeric display complete with self-check, automatic balancing and tracking functions. Bi-dimensional image digital principle of operation. Possibility of adjusting phases and storing up to 100 programs. A RS232 C serial port is also available. Multi-level password protected access reduces human error to a minimum.

Stable, safe and easily serviced mechanics

The machine consists of a conveyor and a metal detector, available in various formats to better adapt to the dimensions of your product and your inspection requirements. The machine thus composed is supported by a structure in stainless steel tubing that gives stability and speeds up cleaning operations. The machine can be configured for belt stop or equipped with appropriate rejection and reject collection systems. All the models comply with the standard on protection, from IP54 to IP65.

Experience

More than 35 years of inspection and quality control: an experience that comes to life in every new model that is designed and built in our establishments. Over 6000 MFN11 are installed at the premises of customers worldwide, who use these machines to guarantee the safety of their product and protect their brand.

Quality

Italian passion for quality is reflected in every machine detail. The attention to every detail, guided by thirty years of experience, is the real added value of PRISMA machines. Finished down to the last detail and made of stainless steel, it is able to withstand intense washing cycles, which can be done extremely quickly, thanks to the conveyor belt quick-disassembly system.

Conformity with standards

The MFN11 with 60 conveyor meets the ISO-FDA HACCP standard, the main directives (including, among others: FDA approvals, FAT/SAT IQ/OQ) and complies with customer guidelines and standards (including, among others: BRC and Marks & Spencer).

Performance and Versatility

Our machines meet high levels of performance and product interchangeability; and wherever they are unable to reach, we can design a tailored system for every requirement.

Return on Investment

Imagine how much you can save with a machine that does not waste product, generate false rejects or force production standstills and that protects the brand. Savings that extend over the years, thanks to the high quality of the materials and the longevity of the machine, which are at top market levels. Our sales team knows how to find the solution that best suits any type of budget and expected financial return.

Convenience and simplicity

A simple, streamlined user interface and years of experience installing and integrating into production lines. All the models can be equipped with Ethernet and USB interfaces to transmit data.

Rejection systems

Several types of rejection systems available to ensure the maximum level of certainty that defective products will be rejected: air-jet, cylinder ejectors.

Reject management systems

All the rejected product bins are protected by a key, allowing only authorised personnel to access them.

Alarms notification

Several types of alarm notifications, both visual and audio.

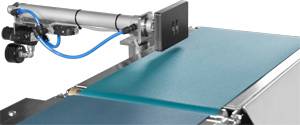

Wind-prevention tunnel

The instrument can be equipped with high resistance guards, which protect from the elements and any contaminants.

Special conveyors

MFN11 with 60 conveyor is available with belt or slat conveyors. PRISMA INDUSTRIALE can help you find the most suitable solution to handle your product.

Quick-disassembly belt

A mechanical securing and release system the drastically reduces machine downtime, both during cleaning and in the event of belt replacement.

Product program memory expansion

The settable product program limit can be exceeded by expanding the available memory and thereby further increasing the machine's versatility.

USB and Ethernet interface

interfaces to export and communicate production data in real time can be implemented on all PRISMA models.

FAT/SAT, IQ/OQ validations

We are available to perform tests and issue the related documents.