1CW11 Pharma

1CW11 Pharma

Dynamic weighing systems

The 1CW11 Pharma is a pharmaceutical checkweigher equipped with an up/down belt that extracts the box directly from the upstream cartoning machine, creates the correct pitch between the products and detects the weight through an electromagnetic cell. This feature allows it to reach extremely high levels of accuracy (from 0.05 g) even at high speeds.

An instrument with the ideal performance to check with extreme accuracy small format, high value cases and boxes.

The equipment features also all the advantages of the T3 electronics and various mechanical devices that simplify the positioning of the extractor in millimetric correspondence with the upstream machine.

| Weighing range | up to 600 g |

|---|---|

| Display division | from 0,01 g (W3) from 0,1 g (T3) |

| Linear speed | up to 100 m/min |

| Throughput | up to 500 ppm |

| Accuracy* | from ± 0,05 g (W3) from ± 0,1 g (T3) |

| Pneumatic supply | 0,6 Mpa |

| Air consumption (for ejection) | 1 Nl |

| Power supply | 230 V 50/60Hz single-phase |

| Power consumption | 700 W |

| Mirror finishing of metal parts | Stainless steel IP54 |

| Climatic environment | from 5°C up to +40°C non-condensing (closed) |

*depending on the weight, dimensions and type of product |

|

Electromagnetic compensation weighing

This technology guarantees the utmost reliability, ensuring accuracy even in the long term and with no problem withstanding external factors like temperature variations and humidity. It is, therefore, the best suited machine to check high value packages, where giving product away for free has a high cost for the company. A version with double load cell is also available, MID approved (T3).

Advanced, intuitive electronics

Digital electronics with a touchscreen display, complete with self-calibration device, mobile average function and 200 storable programs. There are also 2 RS232 C serial ports available and an Ethernet interface to communicate with the outside. Multi-level password protected access reduces human error to a minimum.

Full-optional mechanics, to facilitate in-line installation and exclude environmental interference

The checkweigher consists of three conveyors (feeding, weighing and output), plus an up/down feed belt that extracts the box directly from the upstream cartoning machiner. Particular devices allow to align the extractor perfectly in axis with the tangentials coming out of the cartoner. The reinforced stainless steel structure gives extreme stability to the machine, eliminating possible vibrations and disturbances coming from the working environment, thus allowing to reach very high levels of accuracy even at high speeds. The configuration also features the wind protection tunnel with inspection hatch and safety micro, the open flaps control device, the reject management system and the emergency button.

Experience

37 years of inspection and quality control: an experience that comes to life in every new model that is designed and built in our establishments. The 1CW11 Pharma is the result of continuous work researching innovative technology and developing solutions that fit ever-increasing performance requirements.

Quality

Italian passion for quality is reflected in every machine detail. The attention to every detail, guided by thirty years of experience, is the real added value of PRISMA machines. Finished down to the last detail and made entirely of stainless steel, it is able to withstand intense washing cycles, which can be done extremely quickly, thanks to the quick-disassembly plates.

Conformity with standards

The 1CW11 Pharma meets the ISO-FDA HACCP standard, the main pharmaceutical directives (including, among others: FDA approvals, FAT/SAT IQ/OQ, CFR 21 part 11) and complies with customer guidelines and standards (including, among others: BRC and Marks & Spencer). A version with double load cell is also available, MID approved (T3).

Performance and Versatility

Our machines meet high levels of performance and product interchangeability; and wherever they are unable to reach, we can design a tailored system for every requirement.

Return on Investment

Imagine how much you can save with a machine that does not waste product, generate false rejects or force production standstills and that protects the brand. Savings that extend over the years, thanks to the high quality of the materials and the longevity of the machine, which are at top market levels. Our sales team knows how to find the solution that best suits any type of budget and expected financial return.

Convenience and simplicity

A simple, streamlined user interface and years of experience installing and integrating into production lines. All the models can be equipped with Ethernet and USB interfaces to transmit data.

Alarms notification

Several types of alarm notifications, both visual and audio.

Special conveyors

1CW11 Pharma is available with belt or slat conveyors. PRISMA INDUSTRIALE can help you find the most suitable solution to handle your product.

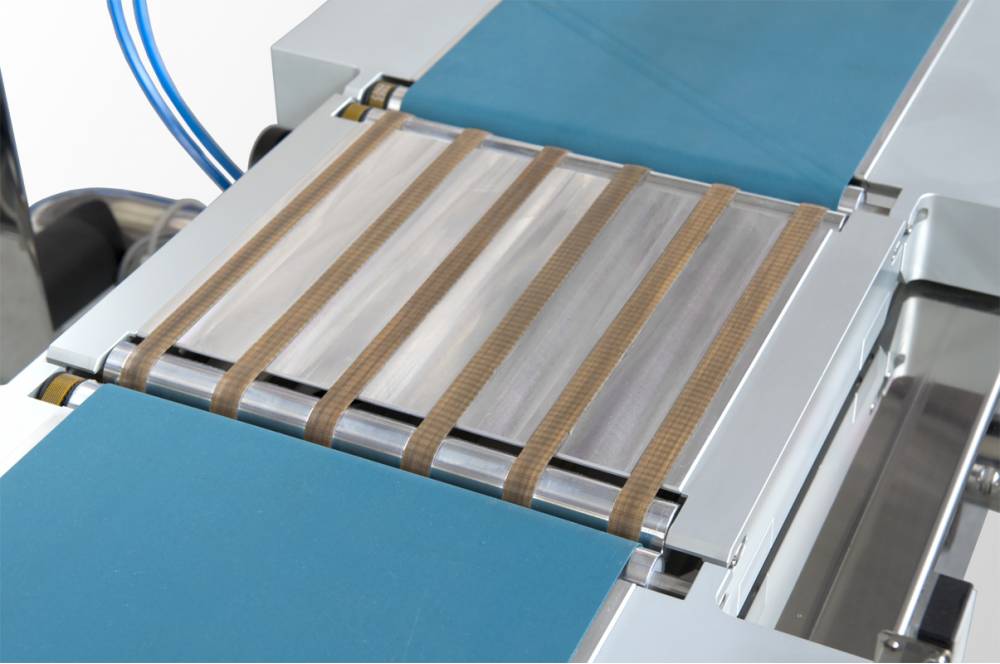

Quick-disassembly belts

A mechanical securing and release system that drastically reduces machine downtime, both during cleaning and in the event of belt replacement.

24-column panel printer

An on-board printer to easily print production data.

Product program memory expansion

The settable product program limit can be exceeded by expanding the available memory and thereby further increasing the machine's versatility.

USB interface

Interfaces to export and communicate production data in real time can be implemented on all PRISMA models. The model is compatible with our DMT software, which allows for convenient direct remote control over the entire production process.

Feed-back function

Allows you to send a signal to the on-board dosing device to reduce mean error, thereby preventing waste due to incorrect dosages and their rejects.

FAT/SAT, IQ/OQ validations, CFR21 part 11

We are available to perform tests and issue the related documents.