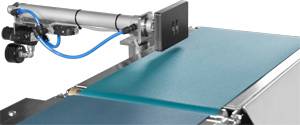

MFN11 with tilted conveyor

MFN11 with tilted conveyor

Customer Solutions

This is a special configuration of the MFN11 metal detector, which is installed on a tilted adjustable conveyor, thereby creating a system that can adapt to the layout of your packaging line.

The infeed has a height that can be defined between 750 and 850 mm and the outfeed is at +100 mm with respect to the infeed. Both heights can be further adjusted by ± 20 mm, thanks to the adjustable feet.

The maximum achievable tilt angle is approximately 18°.

Rejection systems

Several types of rejection systems available to ensure the maximum level of certainty that defective products will be rejected: air-jet, cylinder ejectors.

Reject management systems

All the rejected product bins are protected by a key, allowing only authorised personnel to access them.

Alarms notification

Several types of alarm notifications, both visual and audio.

Wind-prevention tunnel

The instrument can be equipped with high resistance guards, which protect from the elements and any contaminants.

Special conveyors

MFN11 with tilted conveyor is available with belt or slat conveyors. PRISMA INDUSTRIALE can help you find the most suitable solution to handle your product.

Quick-disassembly belts

A mechanical securing and release system that drastically reduces machine downtime, both during cleaning and in the event of belt replacement.

24-column panel printer

An on-board printer to easily print production data.

Product program memory expansion

The settable product program limit can be exceeded by expanding the available memory and thereby further increasing the machine's versatility.

USB and Ethernet interface

interfaces to export and communicate production data in real time can be implemented on all PRISMA models.

FAT/SAT, IQ/OQ validations

We are available to perform tests and issue the related documents.