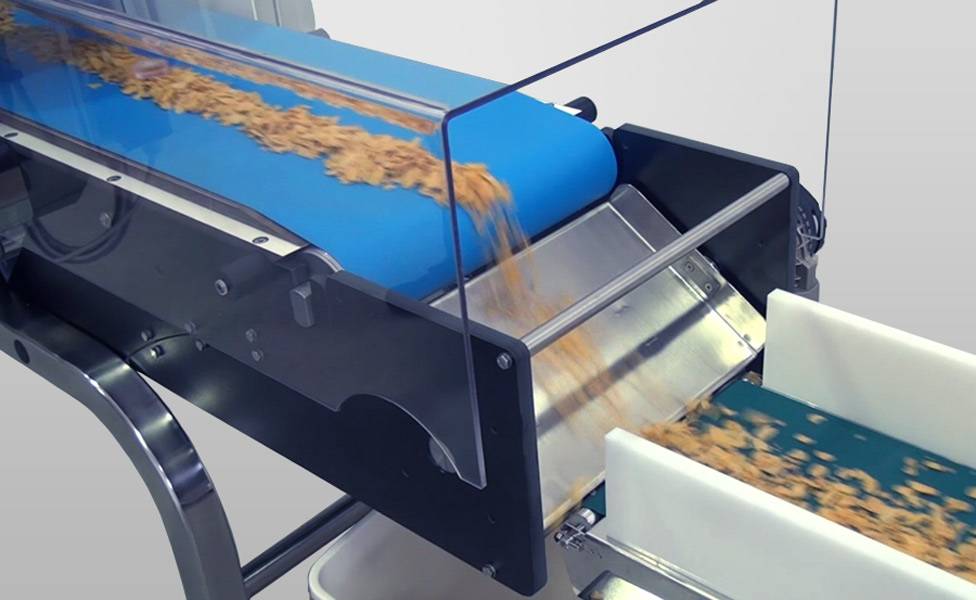

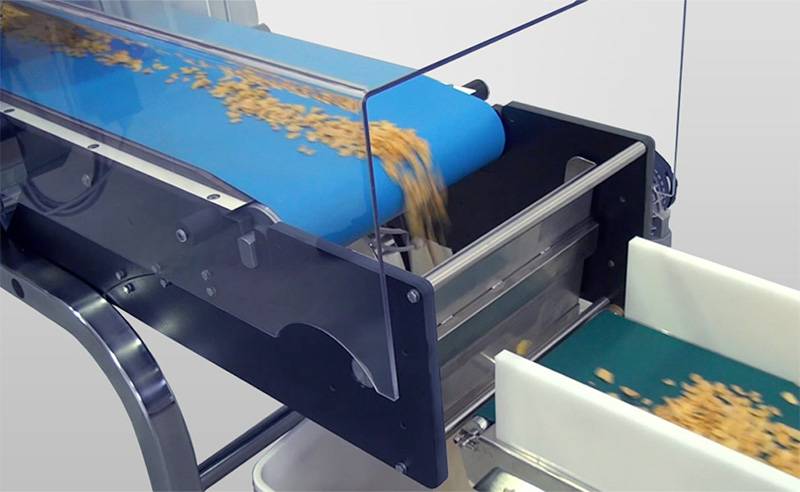

MFN11 with double chute flap

MFN11 with double chute flap

Customer Solutions

This is a special configuration of the MFN11 industrial metal detector, ideal to inspect flows of loose granular product like grains, coffee beans, candies, etc.

The conveyor belt is equipped with an outfeed chute which, when a contaminant detected by the metal head passes, turns on itself, going into counterflow and thereby diverting the range containing the contaminant downward and preventing it from continuing down the line.

Alarms notification

Several types of alarm notifications, both visual and audio.

24-column panel printer

An on-board printer to easily print production data.

Product program memory expansion

The settable product program limit can be exceeded by expanding the available memory and thereby further increasing the machine's versatility.

USB and Ethernet interface

interfaces to export and communicate production data in real time can be implemented on all PRISMA models.

FAT/SAT, IQ/OQ validations

We are available to perform tests and issue the related documents.